PVC blister film for pharma pack Product Features

Enable radiation sterilization

Best-in- class thermoforming

Available in varied sizes and color shades

Finest organoleptic properties so the taste and odor is neutral

Remarkable heat-sealing properties

High dimension stability

Gas transmission and moisture rates are low

Appreciable vacuum formation, toughness, and durability

TECHNICAL SPECIFICATION OF RIGID PVC FILM(BLISTER PACKAGING)

| SR. NO. | PARAMETERS | TEST METHOD | UNIT | STANDARD |

|---|---|---|---|---|

| 01 | Color / Appearance | Visual | — | As per Standard Specimen |

| 02 | Thickness of PVC film | DIN 53479 | Micron | 60 TO 100 ± 12 %, 101 TO 200 ± 10 %,201 TO 400 ± 7 %,401 TO 800 ± 5 % |

| 03 | Density | DIN 53479 | g/ cm 3 | 1.35 ± 0.02 |

| 04 | Tensile Strength | DIN EN ISO527 | Kg/cm2 (Min) | 450 |

| 05 | Dimensional Stability MD | DIN 53377 | % (Max) | 60 TO 100 -12 max, 101 TO 200 – 10 max,201 TO 400 -7 max,401 TO 800 – 5 max |

| 06 | Dimensional Stability TD | DIN 53377 | 60 TO 100 + 5 max,101 TO 200 + 3 max,201 TO 400 + 2 max,401 TO 800 + 1 max | |

| 07 | Width tolerance | mm (Max) | ± 1 | |

| 08 | Vicat Softening Point | ASTM –D 1525 | °C | 74 ± 2 |

| 09 | Identification | FTIR | — | To comply |

Transparent PVC Rigid Film for pharmaceuticals:

Alu-PVC blister pack is very popular in our daily life, such as for OTC oval drugs (over-the-counter) and other small-size dose, chewing gums, dragees, small-piece foods, etc., whereby the rigid PVC is formed to be blisters by heating, then to seal with the aluminum lidding foil on blister packaging machine.

Pharma grade rigid PVC film is almost universally produced on a calendar, a “rigid” or “un-plasticized” material, with low residual monomer content and tailored shrink profiles.

Normally the mono PVC is transparent (clear), which makes the encased product perfectly visible to the consumer, and provides reassurance that the product amount is as advertised or prescribed by doctor.

Specification of Pharma Grade Rigid PVC Film

Normally the gauges 200mic (7.5mils) and 250mic (10mils) offer sufficient material to form blisters of a size that conventional tablets, pills, and capsules can be placed in them and pushed out of the blister.

But for duplex doses, soft gelatin capsule, chewing gums, etc, heavy film shall be used, like 300mic (12mils), even 400mic (16mils).

Here is regular specification of pharmaceutical usage PVC rigid film

| Product code | Structure | Thickness | Weight | Max. width | |||||||||||||||||||||||||

| TTF-PVC-1 | 200mic | 200±20mic | 276±27gsm | 800mm | |||||||||||||||||||||||||

| TTF-PVC-2 | 250mic | 250±20mic | 345±27gsm | 800mm | |||||||||||||||||||||||||

| TTF-PVC-3 | 300mic | 300±20mic | 414±27gsm | 800mm | |||||||||||||||||||||||||

| TTF-PVC-4 | 320mic | 320±20mic | 442±27gsm | 800mm

Specification of Pharma Grade Rigid PVC FilmNormally the gauges 200mic (7.5mils) and 250mic (10mils) offer sufficient material to form blisters of a size that conventional tablets, pills, and capsules can be placed in them and pushed out of the blister. But for duplex doses, soft gelatin capsule, chewing gums, etc, heavy film shall be used, like 300mic (12mils), even 400mic (16mils). They all are available in Tiptop. Here is regular specification of pharmaceutical usage PVC rigid film in Tiptop:

|

Colored Rigid PVC Films for blister packaging

Mono PVC also can be colored with pigment, such as red, amber, white, green, etc., to resiste the visible light, which is one good choice for light-sensitive products.

Meanwhile the PVC with UV filters is availiable in Tiptop, to to resiste the UV rays, which is better barrier for medicines consumed in the areas with rich sun shines.

Tianheng is able to do the opaque PVC blister film as your request. In this case, it is best that you could offer us the original colored sample to prepare our sample for you to test and confirm the quality before the bulk production. Otherwise we could directly offer our colored sample; you check its color and do machine trial, then feedback to Tianheng

Our pharma grade rigid PVC film is being produced of pharmaceutical grade resins, in clean room meeting all GMP requirements. The whole production progress is traceable: each batch of goods is with records of raw materials, production & QA/QC, test & release, delivery, etc, which will be kept at least 3 years.

Please kindly be noted: it will take 5-7days to prepare the sample.

Based on more costs during production, the colored PVC price will be a little higher. For exact one, please inquiry me now.

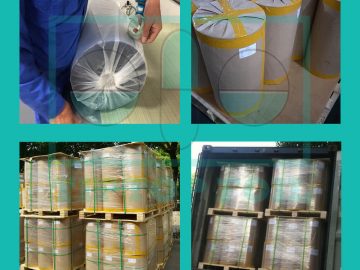

Packing of Pharma Grade Rigid PVC Film:

for silted rolls:

Carton Pack

1.1 each roll is sealed in PE bag, loaded into carton. Cartons stack into shipment container directly.

Aproxi 16-20tons for one 20ft FCL load, which depends on roll widths & weight.

1.2 each roll is sealed in PE bag, loaded into carton. Cartons stack on plywood pallet, with four edge protectors and plastic film wrapping.

Aproxi 16-18tons for one 20ft FCL load, it depends on the width & weight of each roll.

for jumbo rolls:

pharma-rigid-pvc-jumbo-roll-pack

roll is wrapped by PE film and Kraft, with two edge protectors, then stack on plywood pallet by eye-to-sky, and covered by plastic film.

Aproxi 16-20tons for one 20ft FCL load, it depends on the width & weight of each roll.

They both are strong enough and an effective shield against the dusts or damages during shipment to your company,

Hot Tags: pvc blister film for pharma pack, China, manufacturers, suppliers, factory